+GF+ GEORG FISCHER MSA 340

GEORG FISCHER MSA 340

Georg Fischer Central Plastics presents the MSA 340, the next series of electrofusion processors. It’s the pinnacle of engineering: High-end components and customized configurations perfectly support your work flow.

Reliable, easy-to-use and ready for current and upcoming international standards.

Durability • Made of high quality components • Prevention of electrical damage • Water resistant design to IP54 standards

Simplicity • Intuitive user interface • Clear and explicit error messages • USB interface for fusion record downloading and firmware updates

Customization • New software is able to decipher ASTM barcodes and fusion data can be saved into .PDF or .CSV formats • 3 operating modes: Auto-ID, Barcode and Manual • Selectable menu language • Customized traceability options to fit your work flow • GuardianTM Auto-lock rental function

The MSA 340 enhances your daily operations tremendously. As a state-of-the-art tool, it encompasses numerous features which support safety, speed and reliability.

With detailed fusion reports and traceability data – the machine works hand in hand with the operator on the construction site.

Easy and intuitive operation on site can be seen with the practical seven-button keypad used to navigate through the clearly structured menu. With one-button (START/ OK) operation the user is guided from preparation to finalization of the fusion process. Fusion data can be input manually, automatically (in CP mode), or via barcode scan.

The work flow and menu language can also be adjusted to the user’s personal requirements. At the beginning of each fusion additional information, like operator ID and job number, can be attached to the fusion record.

The robust design protects the high quality electrical components and provides excellent heat dissipation allowing fusion in series. The power cord and fusion cables are stored securely in the case lid.

The MSA 340 allows fusion data recording to an internal memory capable of recording up to 1000 fusions. During daily use this interface is shielded against dirt with a protective screw cap.

That data is easily downloaded via standard USB interface to a personal computer for printing and digital storage. No additional data management software has to be installed; the fusion protocol is available in .PDF and .CSV format.

The MSA 340 calibration kit allows customers to calibrate the unit on their own without having to ship it to our facility or even open the box. This reduces shipping expenses and down time, lowering the overall cost of ownership. In addition, the kit itself does not need to be returned to GFCP for regular recalibration.

The MSA 340 has advanced features that comply with the more sophisticated requirements of certain gas applications. The traceability data of the fitting and the pipes can be saved to the fusion record as well as the GPS coordinates of the fusion position.

The data is delivered in PDF or CSV format; both are manageable with customary and free (no license) PC software applications. Each fusion may contain up to 20 different types of data, including fusion parameters, operator ID and job number. The MSA 340 stores the GPS coordinates of the fusion to identify the geographical location and the traceability codes of fitting and pipeline components (ISO).

The MSA 340 is capable of reading, decoding and documenting the new ASTM barcode labels for each fusion performed.

GEORG FISCHER MSA 340

Georg Fischer Central Plastics presents the MSA 340, the next series of electrofusion processors. It’s the pinnacle of engineering: High-end components and customized configurations perfectly support your work flow.

Reliable, easy-to-use and ready for current and upcoming international standards.

Durability • Made of high quality components • Prevention of electrical damage • Water resistant design to IP54 standards

Simplicity • Intuitive user interface • Clear and explicit error messages • USB interface for fusion record downloading and firmware updates

Customization • New software is able to decipher ASTM barcodes and fusion data can be saved into .PDF or .CSV formats • 3 operating modes: Auto-ID, Barcode and Manual • Selectable menu language • Customized traceability options to fit your work flow • GuardianTM Auto-lock rental function

The MSA 340 enhances your daily operations tremendously. As a state-of-the-art tool, it encompasses numerous features which support safety, speed and reliability.

With detailed fusion reports and traceability data – the machine works hand in hand with the operator on the construction site.

Easy and intuitive operation on site can be seen with the practical seven-button keypad used to navigate through the clearly structured menu. With one-button (START/ OK) operation the user is guided from preparation to finalization of the fusion process. Fusion data can be input manually, automatically (in CP mode), or via barcode scan.

The work flow and menu language can also be adjusted to the user’s personal requirements. At the beginning of each fusion additional information, like operator ID and job number, can be attached to the fusion record.

The robust design protects the high quality electrical components and provides excellent heat dissipation allowing fusion in series. The power cord and fusion cables are stored securely in the case lid.

The MSA 340 allows fusion data recording to an internal memory capable of recording up to 1000 fusions. During daily use this interface is shielded against dirt with a protective screw cap.

That data is easily downloaded via standard USB interface to a personal computer for printing and digital storage. No additional data management software has to be installed; the fusion protocol is available in .PDF and .CSV format.

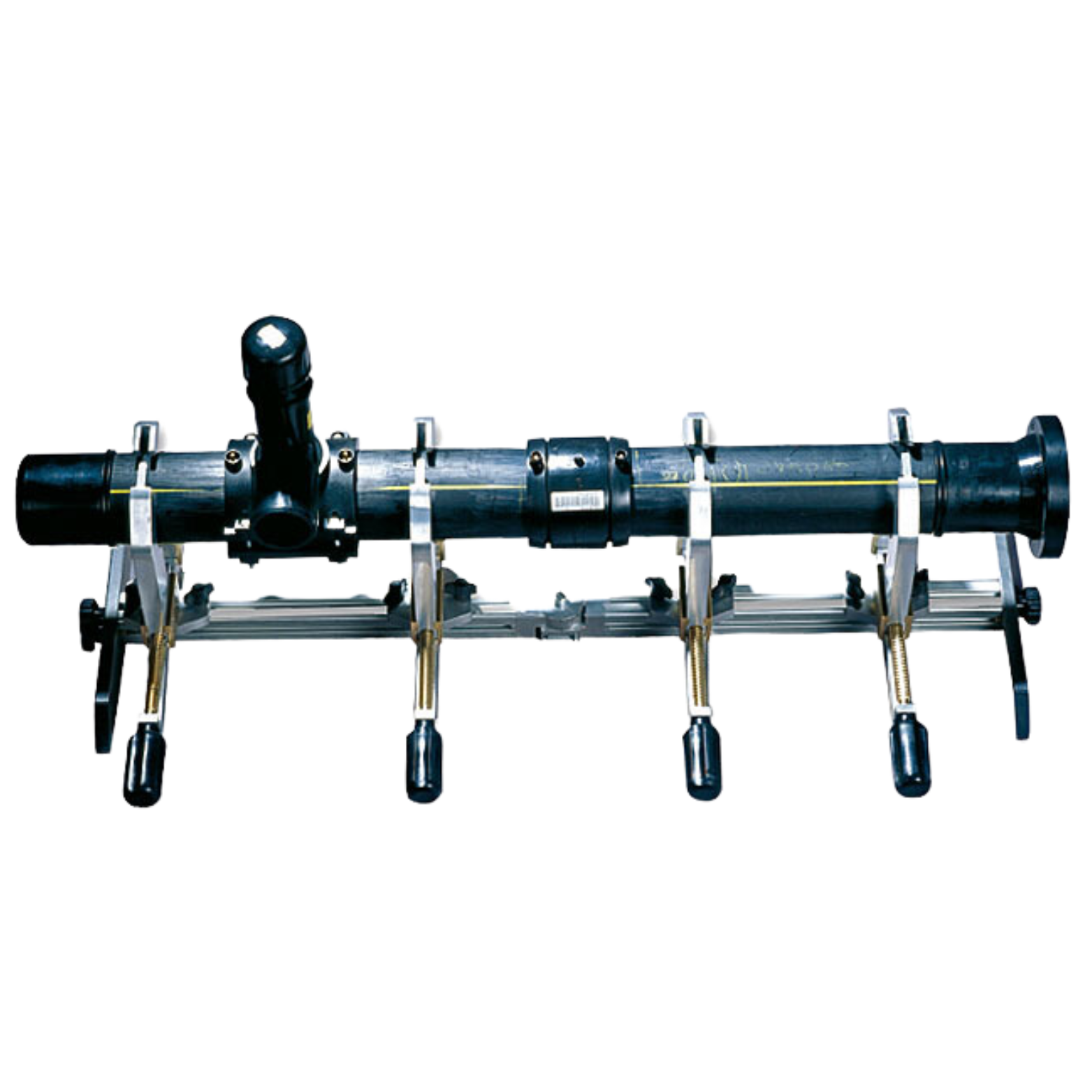

The MSA 340 calibration kit allows customers to calibrate the unit on their own without having to ship it to our facility or even open the box. This reduces shipping expenses and down time, lowering the overall cost of ownership. In addition, the kit itself does not need to be returned to GFCP for regular recalibration.

The MSA 340 has advanced features that comply with the more sophisticated requirements of certain gas applications. The traceability data of the fitting and the pipes can be saved to the fusion record as well as the GPS coordinates of the fusion position.

The data is delivered in PDF or CSV format; both are manageable with customary and free (no license) PC software applications. Each fusion may contain up to 20 different types of data, including fusion parameters, operator ID and job number. The MSA 340 stores the GPS coordinates of the fusion to identify the geographical location and the traceability codes of fitting and pipeline components (ISO).

The MSA 340 is capable of reading, decoding and documenting the new ASTM barcode labels for each fusion performed.

GEORG FISCHER MSA 340

Georg Fischer Central Plastics presents the MSA 340, the next series of electrofusion processors. It’s the pinnacle of engineering: High-end components and customized configurations perfectly support your work flow.

Reliable, easy-to-use and ready for current and upcoming international standards.

Durability • Made of high quality components • Prevention of electrical damage • Water resistant design to IP54 standards

Simplicity • Intuitive user interface • Clear and explicit error messages • USB interface for fusion record downloading and firmware updates

Customization • New software is able to decipher ASTM barcodes and fusion data can be saved into .PDF or .CSV formats • 3 operating modes: Auto-ID, Barcode and Manual • Selectable menu language • Customized traceability options to fit your work flow • GuardianTM Auto-lock rental function

The MSA 340 enhances your daily operations tremendously. As a state-of-the-art tool, it encompasses numerous features which support safety, speed and reliability.

With detailed fusion reports and traceability data – the machine works hand in hand with the operator on the construction site.

Easy and intuitive operation on site can be seen with the practical seven-button keypad used to navigate through the clearly structured menu. With one-button (START/ OK) operation the user is guided from preparation to finalization of the fusion process. Fusion data can be input manually, automatically (in CP mode), or via barcode scan.

The work flow and menu language can also be adjusted to the user’s personal requirements. At the beginning of each fusion additional information, like operator ID and job number, can be attached to the fusion record.

The robust design protects the high quality electrical components and provides excellent heat dissipation allowing fusion in series. The power cord and fusion cables are stored securely in the case lid.

The MSA 340 allows fusion data recording to an internal memory capable of recording up to 1000 fusions. During daily use this interface is shielded against dirt with a protective screw cap.

That data is easily downloaded via standard USB interface to a personal computer for printing and digital storage. No additional data management software has to be installed; the fusion protocol is available in .PDF and .CSV format.

The MSA 340 calibration kit allows customers to calibrate the unit on their own without having to ship it to our facility or even open the box. This reduces shipping expenses and down time, lowering the overall cost of ownership. In addition, the kit itself does not need to be returned to GFCP for regular recalibration.

The MSA 340 has advanced features that comply with the more sophisticated requirements of certain gas applications. The traceability data of the fitting and the pipes can be saved to the fusion record as well as the GPS coordinates of the fusion position.

The data is delivered in PDF or CSV format; both are manageable with customary and free (no license) PC software applications. Each fusion may contain up to 20 different types of data, including fusion parameters, operator ID and job number. The MSA 340 stores the GPS coordinates of the fusion to identify the geographical location and the traceability codes of fitting and pipeline components (ISO).

The MSA 340 is capable of reading, decoding and documenting the new ASTM barcode labels for each fusion performed.

Technical specifications MSA 340 (115 V & 230 V)

Input voltage and frequency 115 V and 230 V (+/- 20%)

Frequency range 50-70 Hz

Suggested generator power requirements 6kVA—all fittings including up to 26” IPS/660mm couplings 3.5kVA coupling up to 8”/225mm, all reducers, and all saddles (service tapping tees, high volume tapping tees and branch)

Input Waveform AC (sine, square or quasisine)

Fusion technique Voltage controlled

Fusion voltage 8-48V~

Operating temperature -10°F – 120°F

Internal temperature -10°F – 180°F

Power cable length 12 ft

Fusion cables length 25 ft

Fusion data input mode Bar code, Manual, CP mode

Capacity of internal memory 1000 fusions

USB port Type A

Barcode reader port Dedicated inputs, DIN 5 connector

Protection factor IP 54

Dimensions 13.5” x 12.5” x 16.8”

Weight 52 lbs

Revision/calibration interval 2 years

Warranty 1 year

4.7mm to 3.0mm connector tip adapters Part # 10001004 (optional)

4.7mm to 4.0mm connector tip adapters Part # 10001005 (optional)

4.7mm Standard connector tip Part # 10001727 (equipped)

4.7mm Connector tip with pogo-pin Part # 10001728 (equipped)

Standards ISO 12176-2 ISO 12176-3 ISO 12176-4 EN 60335-1 (Safety) EN 61000-6-2 (EMC) EN 61000-6-4 and others