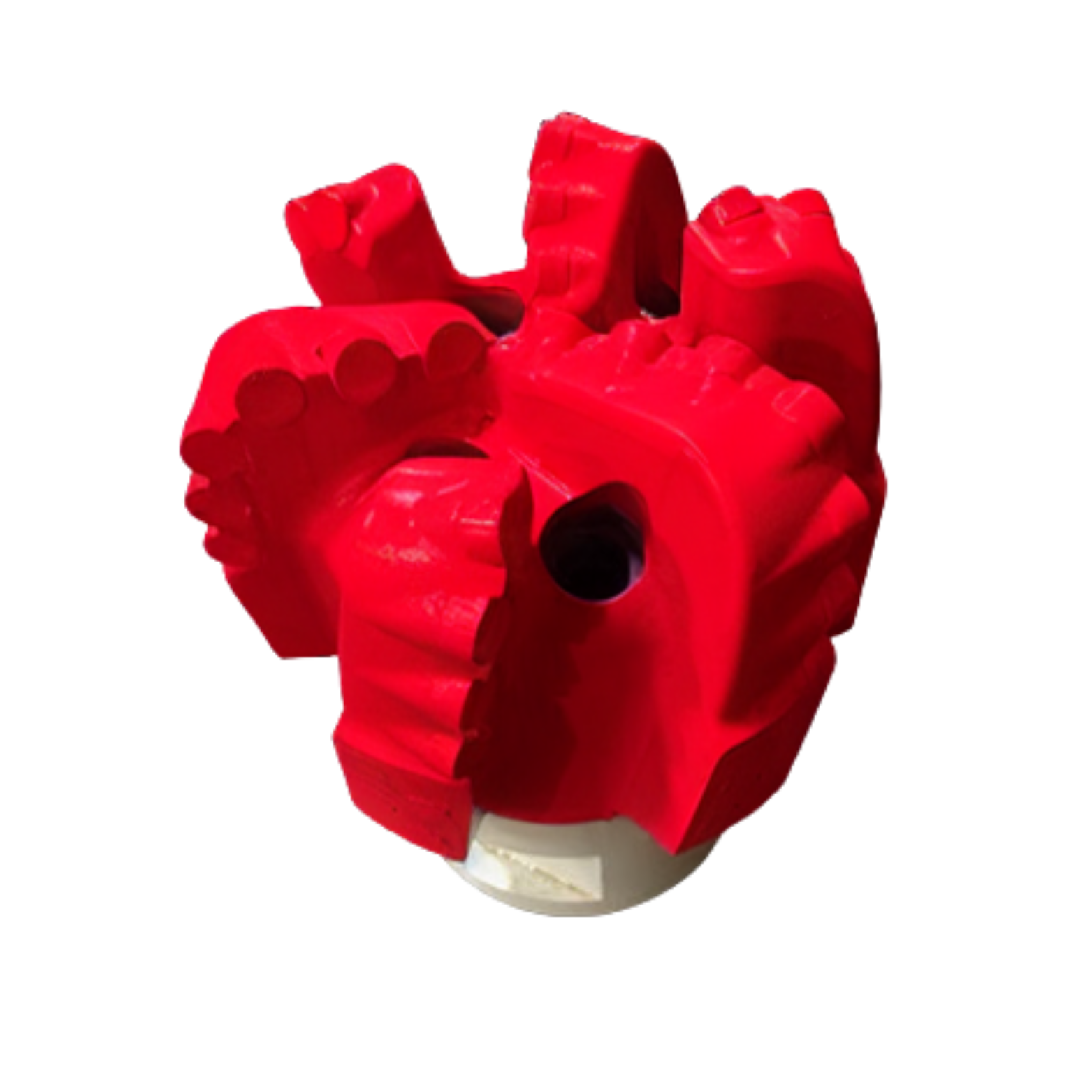

PDC Bits

PRODUCT FEATURES

Available sizes from 5-1/2” up to 12-1/4”

3,4,5 & 6 blade options available for various rock hardness conditions

Nozzle sizes available from 8/32 to 16/32

Standard API pin sizes depending on bit diameter (custom pin options available upon request)

PRODUCT INFORMATION

Made for rapid penetration drilling in a variety of rock types and hardness, PDC bits are the next generation in rotary drilling. Originally developed for the oil & gas exploration industry as a down-hole bit, PDCs have found a home in the HDD industry as well. If you own a rig that is capable of running a mechanical or mud motor, the PDC bit will be your new best friend.

When we say fast penetration rates, we mean FAST. PDC bits (run properly) are capable of outperforming roller cone bits by up to 5:1. If you’re used to seeing a 1’ per minute penetration rate or less, you can, depending on the rock formation, increase your penetration rate to as much as 5’ per minute. The results are truly incredible, but do vary depending on your bit blade configuration and particular drilling conditions.

PRODUCT FEATURES

Available sizes from 5-1/2” up to 12-1/4”

3,4,5 & 6 blade options available for various rock hardness conditions

Nozzle sizes available from 8/32 to 16/32

Standard API pin sizes depending on bit diameter (custom pin options available upon request)

PRODUCT INFORMATION

Made for rapid penetration drilling in a variety of rock types and hardness, PDC bits are the next generation in rotary drilling. Originally developed for the oil & gas exploration industry as a down-hole bit, PDCs have found a home in the HDD industry as well. If you own a rig that is capable of running a mechanical or mud motor, the PDC bit will be your new best friend.

When we say fast penetration rates, we mean FAST. PDC bits (run properly) are capable of outperforming roller cone bits by up to 5:1. If you’re used to seeing a 1’ per minute penetration rate or less, you can, depending on the rock formation, increase your penetration rate to as much as 5’ per minute. The results are truly incredible, but do vary depending on your bit blade configuration and particular drilling conditions.

PRODUCT FEATURES

Available sizes from 5-1/2” up to 12-1/4”

3,4,5 & 6 blade options available for various rock hardness conditions

Nozzle sizes available from 8/32 to 16/32

Standard API pin sizes depending on bit diameter (custom pin options available upon request)

PRODUCT INFORMATION

Made for rapid penetration drilling in a variety of rock types and hardness, PDC bits are the next generation in rotary drilling. Originally developed for the oil & gas exploration industry as a down-hole bit, PDCs have found a home in the HDD industry as well. If you own a rig that is capable of running a mechanical or mud motor, the PDC bit will be your new best friend.

When we say fast penetration rates, we mean FAST. PDC bits (run properly) are capable of outperforming roller cone bits by up to 5:1. If you’re used to seeing a 1’ per minute penetration rate or less, you can, depending on the rock formation, increase your penetration rate to as much as 5’ per minute. The results are truly incredible, but do vary depending on your bit blade configuration and particular drilling conditions.

PDC bits are designed for high speed drilling in shale, limestone, and sandstone formations.

Unlike roller cones, these polycrystalline diamond compact (PDC) drill bits are one piece bodies with no moving parts. The fixed-cutters shave away the rock, making it possible to operate with higher rotation speeds more efficiently in consolidated formations.

POLYCRYSTALLINE DIAMOND COMPACT (PDC) CUTTERS

Diamond is the hardest material known. This hardness gives it superior properties for cutting any other material. PDC is extremely important to drilling, because it aggregates tiny, inexpensive, manmade diamonds into relatively large, intergrown masses of randomly oriented crystals that can be formed into useful shapes called diamond tables. Diamond tables are the part of a cutter that contacts a formation. Besides their hardness, PDC diamond tables have an essential characteristic for drill-bit cutters: They efficiently bond with tungsten carbide materials that can be brazed (attached) to bit bodies. Diamonds, by themselves, will not bond together, nor can they be attached by brazing.