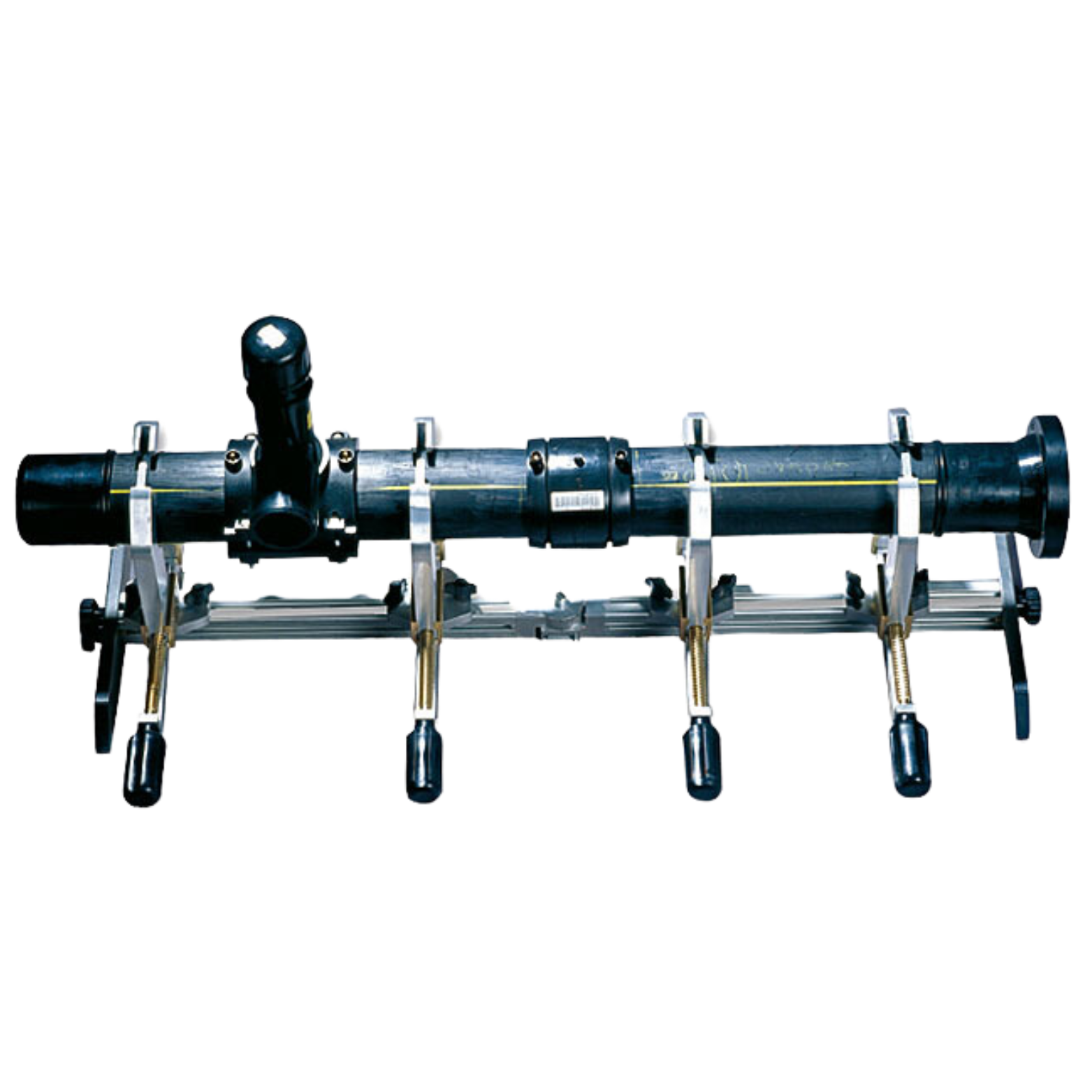

TEST CAP ASSEMBLY

Product Overview

Our test cap assembly is a robust and reliable solution designed to facilitate pressure testing in polyethylene (PE) piping systems. Engineered with precision and built from high-quality materials, this assembly ensures secure and efficient testing, making it an indispensable tool for professionals in the field of pipe installation and maintenance.

Key Features

Durable Construction: Crafted from premium materials, our test cap assembly is designed to withstand rigorous testing conditions, providing long-lasting performance and reliability.

Easy Installation: The test cap assembly features a user-friendly design that allows for quick and straightforward installation, minimizing downtime and enhancing productivity on the job site.

Secure Fit: With a precision-engineered fit, the assembly ensures a leak-proof seal, delivering accurate pressure testing results and ensuring the integrity of your piping system.

Versatile Compatibility: Available in various sizes to accommodate different pipe diameters, our test cap assembly is suitable for a wide range of applications in the water, gas, and industrial sectors.

Reliable Performance: Designed to meet industry standards, this assembly provides dependable performance, ensuring that your pressure testing procedures are conducted safely and effectively.

Applications

Water Distribution Systems: Ensures the integrity and reliability of water supply lines by verifying the strength and leak-proof nature of the installation.

Gas Piping Systems: Critical for testing the safety and functionality of gas pipelines, preventing leaks and ensuring compliance with safety regulations.

Industrial Piping: Suitable for various industrial applications, ensuring that process piping systems are robust and leak-free before they are put into service.

Specifications

Material: High-grade polyethylene and metal components

Sizes Available: 1/2" CTS, 1/2" IPS, 3/4" IPS, 1” IPS, 1-1/4” IPS, 2” IPS

Pressure Rating: Engineered to handle high-pressure testing scenarios

Compliance: Meets or exceeds industry standards for pressure testing

Product Overview

Our test cap assembly is a robust and reliable solution designed to facilitate pressure testing in polyethylene (PE) piping systems. Engineered with precision and built from high-quality materials, this assembly ensures secure and efficient testing, making it an indispensable tool for professionals in the field of pipe installation and maintenance.

Key Features

Durable Construction: Crafted from premium materials, our test cap assembly is designed to withstand rigorous testing conditions, providing long-lasting performance and reliability.

Easy Installation: The test cap assembly features a user-friendly design that allows for quick and straightforward installation, minimizing downtime and enhancing productivity on the job site.

Secure Fit: With a precision-engineered fit, the assembly ensures a leak-proof seal, delivering accurate pressure testing results and ensuring the integrity of your piping system.

Versatile Compatibility: Available in various sizes to accommodate different pipe diameters, our test cap assembly is suitable for a wide range of applications in the water, gas, and industrial sectors.

Reliable Performance: Designed to meet industry standards, this assembly provides dependable performance, ensuring that your pressure testing procedures are conducted safely and effectively.

Applications

Water Distribution Systems: Ensures the integrity and reliability of water supply lines by verifying the strength and leak-proof nature of the installation.

Gas Piping Systems: Critical for testing the safety and functionality of gas pipelines, preventing leaks and ensuring compliance with safety regulations.

Industrial Piping: Suitable for various industrial applications, ensuring that process piping systems are robust and leak-free before they are put into service.

Specifications

Material: High-grade polyethylene and metal components

Sizes Available: 1/2" CTS, 1/2" IPS, 3/4" IPS, 1” IPS, 1-1/4” IPS, 2” IPS

Pressure Rating: Engineered to handle high-pressure testing scenarios

Compliance: Meets or exceeds industry standards for pressure testing

Product Overview

Our test cap assembly is a robust and reliable solution designed to facilitate pressure testing in polyethylene (PE) piping systems. Engineered with precision and built from high-quality materials, this assembly ensures secure and efficient testing, making it an indispensable tool for professionals in the field of pipe installation and maintenance.

Key Features

Durable Construction: Crafted from premium materials, our test cap assembly is designed to withstand rigorous testing conditions, providing long-lasting performance and reliability.

Easy Installation: The test cap assembly features a user-friendly design that allows for quick and straightforward installation, minimizing downtime and enhancing productivity on the job site.

Secure Fit: With a precision-engineered fit, the assembly ensures a leak-proof seal, delivering accurate pressure testing results and ensuring the integrity of your piping system.

Versatile Compatibility: Available in various sizes to accommodate different pipe diameters, our test cap assembly is suitable for a wide range of applications in the water, gas, and industrial sectors.

Reliable Performance: Designed to meet industry standards, this assembly provides dependable performance, ensuring that your pressure testing procedures are conducted safely and effectively.

Applications

Water Distribution Systems: Ensures the integrity and reliability of water supply lines by verifying the strength and leak-proof nature of the installation.

Gas Piping Systems: Critical for testing the safety and functionality of gas pipelines, preventing leaks and ensuring compliance with safety regulations.

Industrial Piping: Suitable for various industrial applications, ensuring that process piping systems are robust and leak-free before they are put into service.

Specifications

Material: High-grade polyethylene and metal components

Sizes Available: 1/2" CTS, 1/2" IPS, 3/4" IPS, 1” IPS, 1-1/4” IPS, 2” IPS

Pressure Rating: Engineered to handle high-pressure testing scenarios

Compliance: Meets or exceeds industry standards for pressure testing